Control the extrusion output and weight per meter, constantly stable product quality.

Shorten start up time of extrusion line and save raw material. Reduce the dependence on personal experiences, skill and fortune.

Achieve raw material saving up to 1%-5% and increase 5% output. The continuous material saving pays back investment within 2 months. *

Full-automatic control / simultaneous control of extruder and hauling machine.

Automatic compensation for changes caused by material bulk density.

Stable production process and improve product quality.

No parametric processing, simpler operation, lower requirements on workers' ability and quality.

Provide scientific judgment data for the stability of the extrusion system and decision data for the maintenance of the extrusion system.

Accuracy error: <0.3~0.5% (Depending on the machine and raw materials)

Satisfy various of precision requirements.

*Calculation based on special output and control conditions.

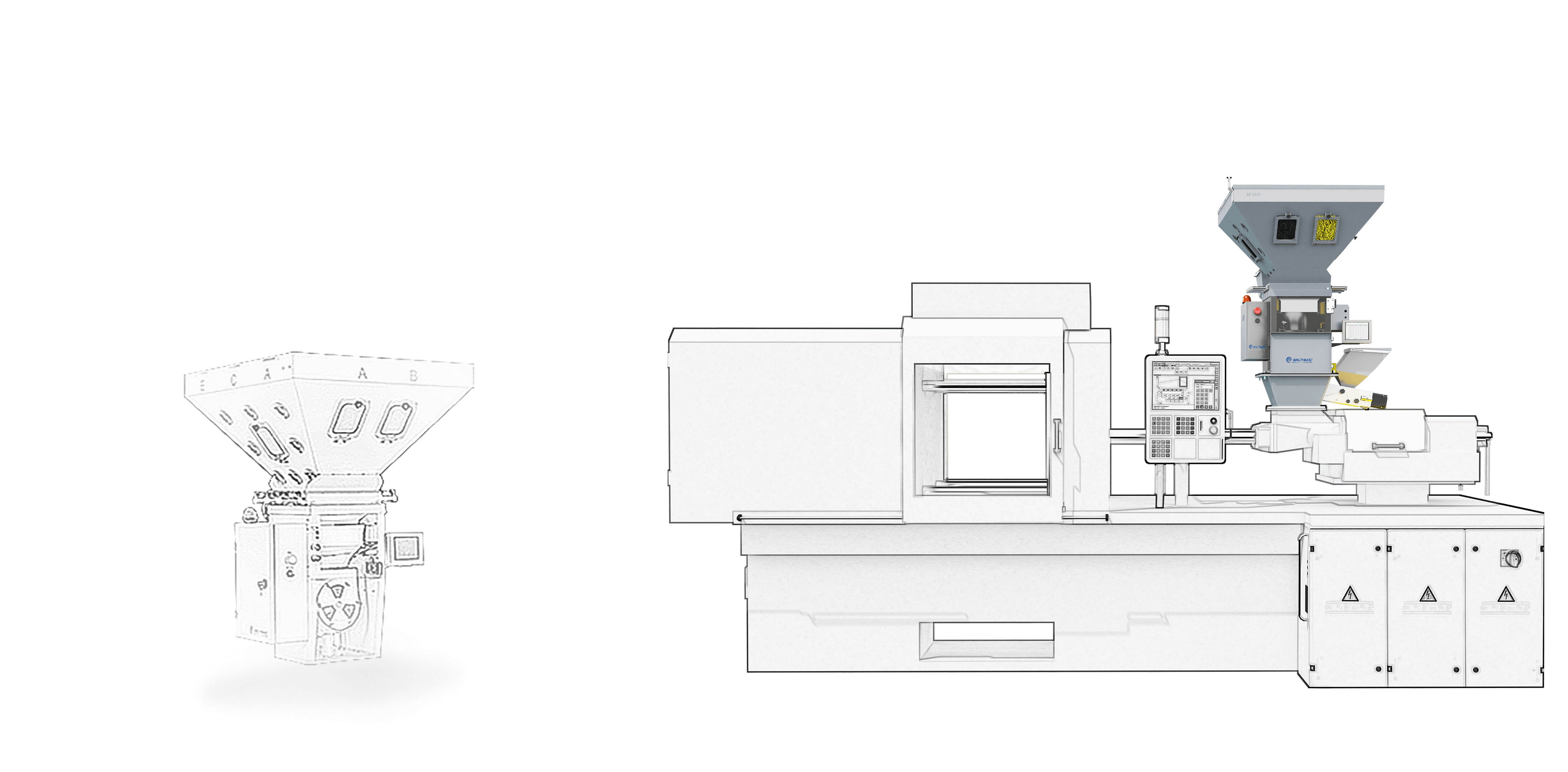

Model | Output (kg/hr) | Size (mm) | Max output (kg/hr) |

GMS-02 | 0.6~60 | 430*290*680 | 60 |

GMS-04 | 1~150 | 430*290*750 | 150 |

GMS-06 | 10~350 | 460*320*810 | 350 |

GMS-12 | 25~500 | 460*320*910 | 500 |

GMS-20 | 35~900 | 510*360*1010 | 900 |

GMS-30 | 60~1250 | 510*360*1230 | 1250 |

中文

中文 English

English Espa?ol

Espa?ol Русский

Русский